Enamelled Flat Aluminum Wire

Rectangular enameled aluminum wire is produced using special-sized molds, creating a rectangular enameled conductor with rounded corners. The conductor can be made of copper, aluminum, or CCA (Copper Clad Aluminum). Compared to copper enameled wire, enameled aluminum wire is easier to wind, and its surface is coated with a robust oxide layer, providing excellent insulation and ensuring a longer lifespan.

In comparison to enameled aluminum round wire, enameled aluminum flat wire is easier to arrange, saving space, offering more flexible wiring, providing better heat dissipation, and achieving higher material utilization. Signi is currently designated as a supplier by renowned companies such as ABB, Chint, Huawei, BYD, Ericsson, and others.

Specification of enamelled flat aluminum wire

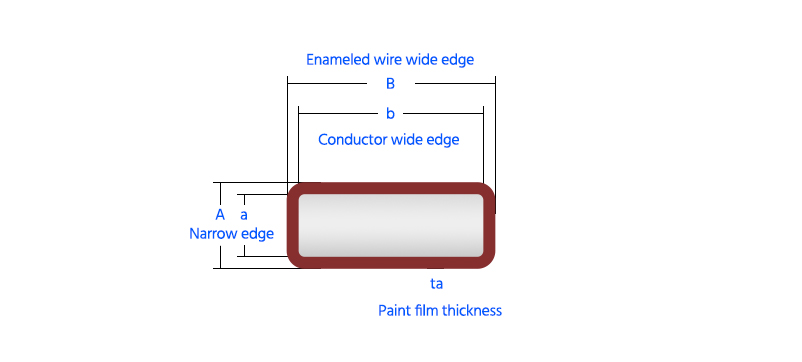

Rectangular enameled wire size range:

Standard sizes: a: 1-5.6mm; b: 2.0-16.0mm;

Maximum sizes: a: 2.0-10mm; b: 16.0-35.0mm;

Enamel-coated round wire thickness (both sides): Level 1 coating 0.05-0.08mm; Level 2 coating 0.12mm; Extra-thick coating 0.45mm;

Coating thickness levels: Level 1, Level 2, Level 3;

Surface: Dark red, smooth, glossy, no paint layer;

Coils: PT25 PT30 PT35 PT60 PT90 PT200 PT270 wooden spools, with a maximum weight per coil of up to 150kg. Conical spools or other types can be provided, and models can be customized according to customer requirements.

Click to view the Signi enameled wire reel specifications

Click to view the Signi enameled wire technical parameter table

Performance features of enamelled flat aluminum wire

| Product Name | 130 class Enamelled Flat Aluminum Wire | 155 class Enamelled Flat Aluminum Wire | 180 class Enamelled Flat Aluminum Wire | 200 class Enamelled Flat Aluminum Wire | 240 class Enamelled Flat Aluminum Wire |

|---|---|---|---|---|---|

| Standard | IEC60317-16 GB/T7095.7 | IEC60317-16 GB/T7095.3 | IEC60317-28 GB/T7095.4 | MW 36 IEC60317–29 GB/T7095.6 | MW 20 IEC60317-47 GB/T7095.5 |

| Thermal Class | 130℃ | 155℃ | 180℃ | 200℃ | 240℃ |

| Enamel Base Coat | Polyester | Modified Polyester | Polyester-Imide | Polyester-Imide | Polyimide |

| Enamel Top Coat | - | Polyamide-Imide | |||

| Cross Section Range | 2 – 80mm2 | 2 – 80mm2 | 2 – 80mm2 | 2 – 80mm2 | 2 – 80mm2 |

| Range of insulation thickness | IEC 60317-0-2G1, 0.06-0.11mmG2, 0.12-0.17mm | IEC 60317-0-2G1, 0.06-0.11mmG2, 0.12-0.17mm | IEC 60317-0-2G1, 0.06-0.11mmG2, 0.12-0.17mm | IEC 60317-0-2G1, 0.06-0.11mmG2, 0.12-0.17mm | IEC 60317-0-2G1, 0.06-0.11mmG2, 0.12-0.17mm |

| Heat shock | 155℃ | 175℃ | 200℃ | 220℃ | 260℃ |

Mechanical properties

| Mechanical properties(Flexibility and adhesion ) | 120 class Enamelled Flat Aluminum Wire | 180 class Enamelled Flat Aluminum Wire | 200 class Enamelled Flat Aluminum Wire |

|---|---|---|---|

| Bending edgewise b≤10mm: | 2xb | 4xb | 4xb |

| Bending edgewise b>10mm | 3xb | 5xb | 5xb |

| Bending flat wise, a all dimensions: | 2xa | 4xa | 4xa |

| Elongation on Break | >32% | >32% | >32% |

| Remarks | b=conductor width ; a=conductor thickness | ||

Electrical properties

| Electrical properties(Breakdown Voltage) | 120 class Enamelled Flat Aluminum Wire | 180 class Enamelled Flat Aluminum Wire | 200 class Enamelled Flat Aluminum Wire |

|---|---|---|---|

| At room temperature Grade 1 | >1500V | >1500V | >1500V |

| At room temperature Grade 2 | >2500 | >2500 | >2500 |

| At high temperature Grade1 | >750V | >750V | >750V |

| At high temperature Grade 2 | >1500V | >1500V | >1500V |

Chemical properties

| Chemical properties | 120 class Enamelled Flat Aluminum Wire | 180 class Enamelled Flat Aluminum Wire | 200 class Enamelled Flat Aluminum Wire |

|---|---|---|---|

| Resistance to resins | 5H | 3H | 4H |

| Solvents | 2H | 3H | 4H |

| Transformer oils | Excellent | Very Good | Very Good |

| Refrigerant | - | Good | Very Good |

Signi Enameled Aluminum Flat Wire Hot selling product

-

130 class enameled aluminum flat wire

Temperature resistance: 130°C

Heat shock resistance: 150°C

-

155 class enameled aluminum flat wire

Temperature resistance: 155°C

Heat shock resistance: 175°C

-

180 class enameled aluminum flat wire

Temperature resistance: 180°C

Heat shock resistance: 200°C

-

200 class enameled aluminum flat wire

Temperature resistance: 200°C

Heat shock resistance: 220°C

-

220 class enameled aluminum flat wire

Temperature resistance: 220°C

Heat shock resistance: 240°C

-

240 class enameled aluminum flat wire

Temperature resistance: 240°C

Heat shock resistance: 260°C

-

Copper-Clad Enamelled Wire

Lightweight, excellent conductivity

Easy to process

-

Heavy Coating Enameled Wire

Base coat thickness: 0.5-0.8mm

Second coat thickness: 1.2mm

-

Extra-Large Enameled Flat Wire

Maximum dimensions: 3.5*35mm

Suitable for vertical winding

Advantages of enamelled flat aluminum wire

- Excellent Heat Stability: The enameled aluminum flat wire exhibits outstanding heat stability, maintaining stable performance in high-temperature environments without being significantly affected by temperature variations. This makes it suitable for various electrical devices with demanding temperature requirements.

- Excellent Dielectric and Mechanical Properties: The enameled aluminum flat wire excels not only in electrical insulation but also in mechanical performance, contributing to the reliability and longevity of electrical equipment.

- Chemical Resistance: The enameled aluminum flat wire demonstrates excellent resistance to common solvents and coolants. In industrial environments, it maintains stable performance, resisting corrosion from chemical substances.

- Good Insulation: With a conductor cross-section yield of 97%, and similar thickness of corner and surface enamel films, it facilitates insulation maintenance in coil winding.

- Low Friction Coefficient: When inserted into slots, the enameled aluminum flat wire exhibits better sliding performance due to its flat cross-section, reducing the friction coefficient and enhancing the efficiency and performance of electrical equipment.

- High Conductivity: With a larger surface area compared to enameled round wire at the same cross-sectional area, it reduces the "skin effect" and is suitable for high-frequency conduction work.

Application of polyesterimide wire enamel

- Power Transformers: Used in power transformers, AC ultra-high voltage transformers, and DC converter transformers.

- Winding for Transmitting High-Frequency Signals: Applied in windings for transmitting high-frequency signals, such as demagnetizing coils, high-voltage coils, etc.

- Manufacturing of Arc Welding Machines: Utilized in the manufacturing of arc welding machines, including large and medium-sized motor windings, compressor windings, deflection coils, etc.

- Large Low-Voltage High-Current Electrical Appliances: Found in large low-voltage high-current electrical appliances, such as dry-type transformers, reactors, rectifiers, electromagnetic iron removers, etc.

- Motors, Generators, New Energy Vehicles: Used in electric motors, generators, and components for new energy vehicles.

Enameled aluminum flat wire vs. enameled copper flat wire

- Easy to wind: Enameled aluminum flat wire is easier to wind, which provides greater flexibility in the manufacturing and wiring process of electrical equipment.

- Good insulation effect: There is a strong oxide film on the surface of the enameled aluminum wire, which provides good insulation effect and makes it have a long life in use.

- High heat-resistant temperature: Due to the insulation effect of the aluminum film layer, the heat-resistant temperature of enameled aluminum flat wire can be 20 degrees higher than that of enameled copper flat wire.

- Lightweight: Aluminum is one-third lighter than copper. Using enameled aluminum flat wires can significantly reduce the weight of electrical equipment and reduce production costs.

- Adhesion: Aluminum conductors adhere easily to solid objects, helping to improve connectivity and conductivity.

- Reduced transportation costs: Due to the lightweight properties of aluminum, enameled aluminum flat wires can reduce freight and transportation costs during transportation.

Signi's wire enamel quality control system includes

- Raw material inspection: Rigorous standards are applied to select high-quality aluminum rods, ensuring the base material's superior quality. This step is fundamental to ensuring the performance and reliability of the final product, as the quality of the aluminum rods directly affects the end product.

- Drawing inspection: Emphasis is placed on the high quality and reliability of the insulated conductor. This involves precise selection of raw materials, considering not only the production process but also meeting design specifications to satisfy customer requirements.

- Semi-finished product production inspection: Before coating, processes like drawing (for round wire) or flattening (for rectangular wire) are employed to adjust the dimensions of the conductor (copper or aluminum). This step ensures the uniformity of the conductor and compliance with specifications, providing a solid foundation for subsequent enamel coating.

- Finished product inspection: Particular focus is given to ensuring the quality of winding wires, the most critical part of the product where no compromises can be tolerated. Signi adheres to recognized IEC standards as the minimum quality benchmark to ensure that each finished product meets internationally accepted quality standards.

- Packaging and labeling inspection: The production is integrated with a reviewed quality control system to ensure that product packaging complies with specifications. This is supported by a well-trained technical team and fully equipped laboratory facilities.

- Up to 13 testing items: To ensure the reliability of wire enamel in its final use in motors, transformers, or coils, Signi conducts up to 13 testing items. With a comprehensive quality control and packaging system, the company ensures that any product issues can be traced and provides customers with a more reliable guarantee.

Signi enameled wire technical parameter table

Conductor corner radius

| Nominal thickness of conductor (mm) | corner radius(mm) | Tolerance | |

|---|---|---|---|

| over | Up to and including | ||

| – | 1 | 0.5 nominal thickness | +/-25% |

| 1 | 1.6 | 0.5 | +/-25% |

| 1.6 | 2.24 | 0.65 | +/-25% |

| 2.24 | 3.55 | 0.8 | +/-25% |

| 3.55 | 5.6 | 1 | +/-25% |

Conductor Tolerance

| Nominal width or thickness of the conductor (mm) | Tolerance | |

|---|---|---|

| over | Up to and including | |

| – | 3.15 | 0.03 |

| 3.15 | 6.3 | 0.05 |

| 6.3 | 12.5 | 0.07 |

| 12.5 | 16 | 0.1 |