High Purity Aluminum Wire Supplier

Signi provides EC grade high-purity aluminum wire and coils for enamel-insulated wire, cable manufacturing, and other electrical applications. With purity up to 99.99%, it offers improved conductivity and can function as a superconductor at 1.1-1.2K.

The popular 1070 and 1060 pure aluminum wires are mainly used for electrolytic capacitor leads and in special electrical industries requiring high-purity aluminum materials.

- Smooth and clean surface without dents, scratches, oil stains, or oxidation.

- Neat cutting edges without burrs.

- First-pass inspection pass rate of 98%, customer satisfaction rate of 95%.

Nominal dimensions and tolerance of Signi pure aluminum wire

Signi produces high-purity aluminum round wire ranging from 9.5mm to 25mm in diameter. Hot selling diameters include: 7.5mm, 9.5mm, 12.0mm, 15.0mm, 19.0mm, 24.0mm... Customization available for other requirements.

| Nominal dimensions and tolerance | |||||||

|---|---|---|---|---|---|---|---|

| Nominal Diameter | 9mm | 9.5mm | 12mm | 15mm | 19mm | 23mm | 25mm |

| Diameter tolerance, not more | +/-0.3 mm | +/-0.3 mm | +/-0.4 mm | +/-0.5 mm | +/-0.8 mm | +/-1.0 mm | +/-1.0 mm |

| Ovality, not more | 0.4mm | 0. 3mm | 0.4mm | 0.5mm | 0.6mm | 0.8mm | 0.8 mm |

Signi's high-purity aluminum wire is available in coiled form. Reference coil dimensions: Inner coil diameter 1100mm; outer coil diameter 2200mm; coil height 1600mm.

Chemical component of 1060 1070 aluminum wire

| Alloy | 1070 | 1060 |

|---|---|---|

| Si | 0.2 | 0.25 |

| Fe | 0.25 | 0.35 |

| Cu | 0.04 | 0.05 |

| Mn | 0.03 | 0.03 |

| Mg | 0.03 | 0.03 |

| Cr | — | — |

| Ni | — | — |

| Zn | 0.04 | 0.05 |

| Ti | 0.03 | 0.03 |

| Zr | — | — |

| Al | 99.7 | 99.6 |

Electric performance of 1070 pure aluminum wire

| Temper | Resistivity Ω·m | Conductivity %IACS min |

|---|---|---|

| O | 2.82×10-8 | 61% |

| H14 | ||

| H18 |

Mechanical performance of 1070 pure aluminum wire

| Temper | Tensile strength Rm Mpa | Usual Elongation A100 % | |

|---|---|---|---|

| Min | Max | ||

| O | - | 85 | 35 |

| H14 | 95 | - | 5 |

| H18 | 125 | - | 3 |

Advantage of Signi high purity aluminum wire

- High-purity aluminum wire is the lightest, reducing overall cable and conductor weight, benefiting large-scale power projects, transmission towers, and hanging equipment load capacity.

- High-purity aluminum wire's minimal impurities and low resistance make it ideal for high-frequency, high-precision electrical applications, reducing circuit power consumption.

- Pure aluminum is highly ductile, easily stretched, extruded, and rolled into various shapes, making it much easier to manufacture aluminum round wire, flat wire, or aluminum wire with complex cross-sections.

- Aluminum resists atmospheric and water corrosion well, even against most acids and organics. Surface coatings like paint further improve its corrosion resistance.

- Signi's pure aluminum wire is free from low-temperature brittleness. As temperatures decrease, its strength and ductility increase instead of decreasing.

- Pure aluminum has a high thermal conductivity, aiding in heat dissipation, making it suitable for applications requiring excellent heat dissipation, such as in electrical appliances.

- Pure aluminum is relatively easy to weld, simplifying the welding and connection process of aluminum wires. This is crucial for wire connections and maintenance in electrical power systems.

- Suitable for various basic power applications including power cables, electrolytic capacitors, electronic components, refrigeration systems, evaporators, condensers, and other critical components.

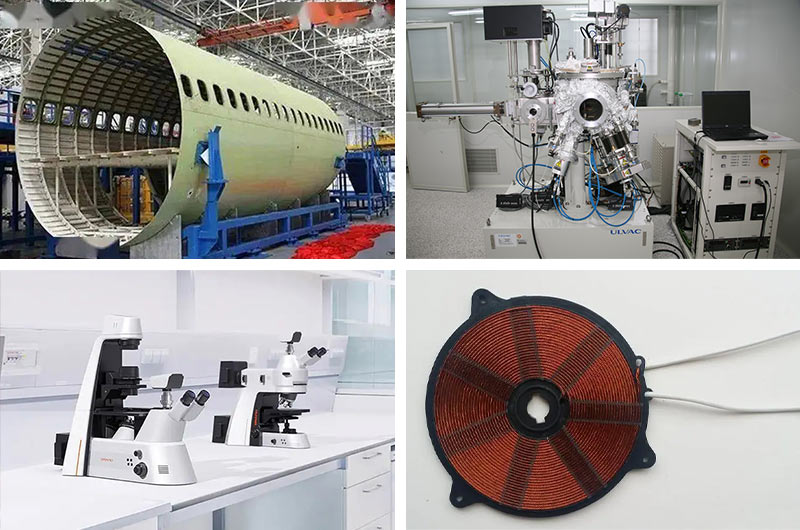

Signi high purity aluminum wire cooperation field

- Conductor materials for electronics and semiconductors;It’s high purity and low impurity content improve conductivity and reduce impurity-related impacts on device performance.

- Lightweight electrical connectors, wires, and cables in aerospace applications; It’s lightweight enhances aircraft performance with their weight-saving design and high conductivity.

- Precision instrument manufacturing. High purity aluminum wire can be used to prepare highly sensitive sensors, measuring equipment, etc., ensuring the stability and accuracy of the instrument.

- Manufacturing of wires and connectors in medical equipment, such as electronic medical devices. High purity aluminum wire ensures the reliability and stability of the equipment.

- Electric furnace coils in high-temperature furnaces. The high melting point and oxidation resistance of high-purity aluminum wire can meet some special applications in high-temperature environments.